VERSATILE

Fasteners for

Any Project & purpose

BMD offers a range of fastener lines through QuickBuild Pro, ready for use in wood, cement, gypsum, and drywall applications.

QuickBuild Pro fasteners

Our fasteners endure rigorous testing to ensure a quality product.

We regularly put our fasteners through a battery of tests to ensure our screws can last under the harsh conditions of real-world project use. We implement the following tests for every QuickBuild Pro fastener product:

- Tension

- Profile

- Torque

- Bending

- Penetration Speed

- Cutting

- Grinding

- Mounting Press

- Hardness

- X-Ray

- Salt Spray

- Complete Inspection Report

Fastener identification

Look for these icons for quick identification.

BMD carries a wide assortment of threaded fasteners to help you complete your project efficiently and correctly. We offer threaded fasteners in a variety of lengths, shank thicknesses, drive types, thread types & point types that are geared towards specific applications to help you accomplish your project quickly & effortlessly.

Drives

Phillips

The most common screw drive type. Phillips drives are designed to cam-out, preventing over-tightening.

Slotted

The first type of screw drive to be developed. Still commonly used in hand-driven applications where little torque is required.

Square

Also known as a Robertson or Scrulox drive, square drives are resistant to cam-out, allowing the screw to stay on the tool tip without the user needing to hold the fastener in place.

TORX ™ / STAR

Torx, also sometimes referred to as star drives, are designed to prevent cam-out and for high-torque applications. Greater torque can be applied to the fastener, allowing for over-tightening.

Socket

Has a 6-sided socket that is commonly driven by Allen wrenches or hex keys.

Hex

Turned by using the outside of the head rather than the inside. Usually driven by an appropriately sized socket.

Coatings

Phosphate

Chemical etching process using phosphate intended for interior use.

Zinc

Electroplating process using zinc intended for interior use.

Yellow Zinc

Electroplating process using yellow zinc intended for interior use.

RUSPERT®

Electroplating + coating process for superior corrosion resistance.

Exterior Grade

Pollutant-free ceramic coating for high corrosion applications. Ideal for use with treated lumber.

SKT®

Nanometer technology process for high corrosion applications. Ideal for use in ACQ treated lumber.

Points

Sharp

Sharp points are often found on threaded fasteners intended for use in soft wood, drywall, plywood, composite and light metals.

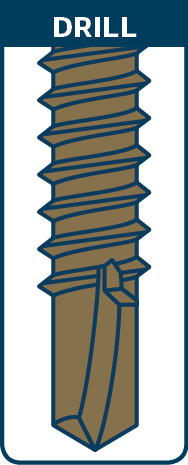

Self-Drill

Self-drill points have a drilling tip that eliminate the need for hole preparation. Self-drill points are often found on fasteners intended for harder surfaces such as cement boards or heavier gauge sheet metals.

Type-17

Type-17 points have a thread cutting point with a sharp tip. The fluted point helps to capture and remove chips when driving the fastener. Commonly used in wood and composite.

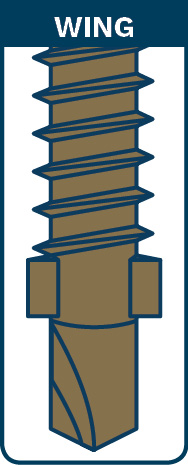

Wing-Tip

Wing-tip points are for use in fastening wood to metal applications. The wings ream a clearance hole in the wood but are designed to break off when coming in contact with metal. Also known as reamer points.

Threads

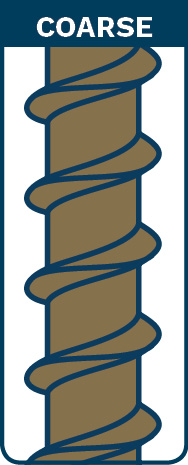

Coarse Thread

Coarse thread fasteners have fewer threads in a defined length with larger size threads relative to the shank diameter. Coarse thread fasteners drive faster and have greater holding power for softer woods such as pine and cedar.

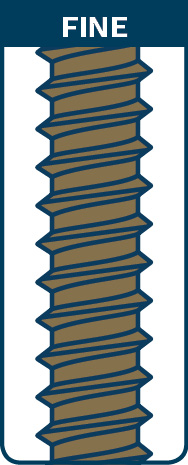

Fine Thread

Fine thread fasteners have more threads in a defined length with smaller size threads relative to the shank diameter. Fine thread fasteners drive slower and are preferred for harder substrates such as into metal or hard woods like oak or cherry.

Exceeds All ASTM Requirements

QuickBuild Pro fasteners provide security in a fully tested fastener for job site use.

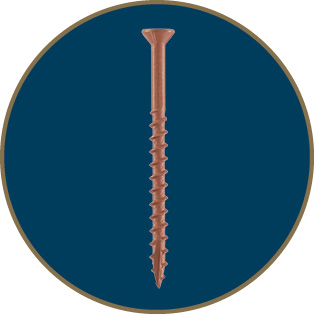

Deep Well-Formed Recess

Allows easy seating of the fastener and cam-out when at proper depth. Pushes drive torque through the screw for faster penetration and prevents wobbling.

Core Steel Strength

Tested to exceed industry standards which allows fasteners to maintain internal integrity.

Cutting Thread

Delivers smooth entry and allows fastener to cut through material quickly.

Threads

Designed for increased holding power.

Strong Coating

Increased corrosion resistance.

Sharp Point

Provides easy penetration into wood and light gauge metals.

Type-17 Point

Captures chips and helps penetrate quicker into harder woods.

Self-Drilling Point

Penetration into heavier gauge metals.

SECURE

Performs on the Jobsite every time

QuickBuild Pro is BMD’s line of high-quality threaded fasteners. QuickBuild Pro’s easy to use fasteners provide faster penetration, are made stronger, last longer and tested to meet or exceed industry standards.

Our vast selection of threaded fasteners allows you to select the proper fastener for your project. With multiple fasteners for exterior and interior wood, heavy and light gauge metal connections, we have a threaded fastener to meet your needs.

QUICK

Straightforward Design for easy selection

The packaging of QuickBuild Pro products is designed for maximum clarity, providing you with the information you need to choose the product that's perfect for the project and application, every time.

Color Coded System

Quick selection by application.

Prominent Product Size

Large size description for easy identification.

Product Description

Product description of fastener type and finish for correct selection.

Product Image

Product image for quick visual identification.

Large Display Window

Large size description for easy identification.

Testing & Certification for our products

Quickbuild Pro products are built to perform.

QuickBuild Pro threaded fasteners are manufactured via select mills starting with high-grade steel bars. The steel bars are then turned into 5.5 mm coils that are further “pulled” to exact diameters dependent on the type of fastener. The coils are then cut to length, headed, point formed, threaded and heated treated with quality control checks performed every step. QuickBuild Pro fasteners are fully tested after the coating process, and are given a final inspection during packaging.

Tests

- Tension

- Torque

- Bending

- Hardness

- Salt Spray

- X-Ray

- Cutting

- Penetration Speed

Certifications

- SAEJ78

Dimensional specifications and performance requirements.

- ASTM C1002

Attaching Gypsum to steel studs less than 0.033 or 0.84mm thick.

- ASTM C1513

Attaching Gypsum to steel studs with drill screws.

- ASTM C954

Attaching steel studs with 0.033/0.84mm to 0.112/2.84mm thicknesses.

- ISO 14001

Environmental management system to reduce impact and increase efficiencies.

- ISO 9001

Quality management system that is audited by 3rd parties to certify compliance.

- B117

Salt spray requirements.